- Products

- Die Spotting Press

- Vertical Die Spotting Machine

- Horizontal Die Spotting Machine

- Hardware Die Spotting Machine (NCC Series)

- CNC Gun Drilling Machine

- Single Shaft Gun Drilling Machine

- 2-Axis Gun Hole Machine

- 3-Axis Gun Drilling Machine

- 4-Axis Gun Drilling Machine

- Drilling and Milling Compund Machine

- Mold Turnover Machine

- Electric Magnetic Chuck

- Electric Magnetic Chuck for CNC Machine

- Electric Magnetic Chuck for Mobile Phone

- Hydraulic Press Machine

- Horizontal CNC Milling Machine

- CNC Drilling and Milling Machine

- NCB Drawing Press

- Spray and Absorb Drilling Machine

- Rotary Work Bench

- Quick-Die Change System

- Permanent Magner Lifter

Vertical Die Spotting Press (NC Series)Read More

Description:

NC vertical die spotting machine is widely used in repair or verification of mold and it is suitable for medium and large mold. Based on the conventional vertical mold spotting press, NC die spotting machine adopts electric magnetic chuck, thus it is unnecessary to fix the screws. Therefore, it can save time and save labor. NC vertical die spotting machine is the only one that adopts electric magnetic chuck in the world. Besides, it is very convenient to operate it with computer control and man/machine interface. The die spotting press can work together with mold turnover machine.

Application:

NC vertical die spotting machine is mainly applied in repair or verification of plastic die, hardware casting die. NC vertical die spotting press replaces the traditional simple fitting of knocking by copper bar because of its fast and automation operation, which greatly improves efficiency and precision of die spotting press. NC vertical die spotting machine is the main product of our company which takes a great effort and time of our technician to develop. It absorbs the essence advantages of products at home and abroad.

Components:

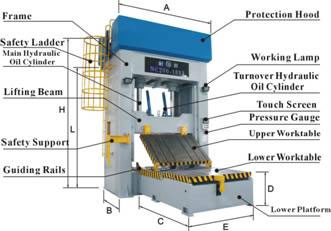

Front view

Front view Side view

Side view

Features:

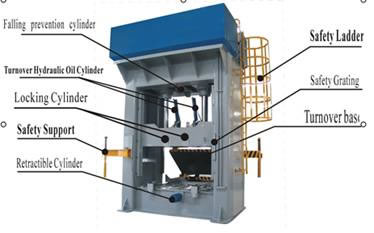

- 1. Perfect safety facilities

There are safety facilities to guarantee safety of men, like safety grating, anti-falling oil cylinder, locking cylinder and safety supporting frame and other prevention facilities. - 2. High precision

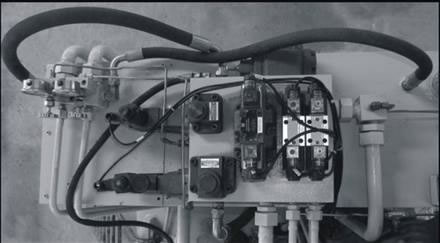

NC vertical die spotting machine has high precision because hydraulic system adopts vibration-absorption facilities which will reduce hydraulic impact. - 3. No damage

Hydraulic system is equipped with low-pressure protection facilities, to prevent damages caused by collision and insertion. - 4. Good red lead can be achieved because is high speed of vertical die spotting machine.

- 5. Small formation

Small-tonnage type (below 200T) frame adopts welding type frame structure. While large-tonnage type (above 300T) frame adopts welding type and separated frame. Separated parts are connected through green columns and screws. Frame and sliding table are processed through tempering treatment, for the advantages of no stress, large rigidity and small formation. - 6. Flatness

Upper and lower working benches and guide rails of pressure-plate vertical die spotting machine are made from nodular cast iron, with advantages of sound flatness, high precision and small deformation. - 7. The die spotting press is equipped with security facilities.

Anti-falling facilities

Anti-falling facilities

Locking facilities

Locking facilities

Safety supporting facilities

Safety supporting facilities

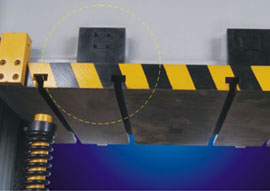

Rating protection

Rating protection

detail

detail

Parameter:

| Model | Sizes of all parts | |||||||||||||

| vertical die spotting machine | Total height of machine(H) | Height of main Frame(L) | Width of main frame(A) | Length of main frame(B) | Length of lower platform(C) | Height of lower platform(D) | Width of lower platform(E) | Length of working bench(F) | Width of working bench(G) | Thickness of working bench、(I) | Land area of t machine | Weight of machine (T) | Sizes of oil tank(length×width×height) | Fueling charge (L) |

| NC30 | 3300 | 2600 | 1560 | 1200 | 1550 | 500 | 920 | 800 | 600 | 75 | 2680×1980 | 4.8 | 920×520×380 | 150 |

| NC50 | 3840 | 2845 | 1725 | 1370 | 1790 | 530 | 1110 | 1000 | 700 | 75 | 2900×2150 | 6.5 | 1100×600×500 | 280 |

| NC70 | 4160 | 2845 | 1725 | 1370 | 1790 | 530 | 1110 | 1000 | 700 | 75 | 2900×2150 | 6.5 | 1100×600×500 | 280 |

| NC100 | 4250 | 3160 | 2250 | 1600 | 2310 | 550 | 1410 | 1300 | 1000 | 95 | 3830×2680 | 12 | 1400×640×600 | 430 |

| NC120 | 4650 | 3160 | 2250 | 1600 | 2310 | 550 | 1410 | 1300 | 1000 | 95 | 3830×2680 | 12 | 1400×640×600 | 430 |

| NC150 | 5150 | 3660 | 2560 | 1700 | 2530 | 735 | 1620 | 1500 | 1100 | 105 | 4170×3060 | 18 | 1450×640×700 | 580 |

| NC200 | 5680 | 4260 | 3166 | 2280 | 2950 | 830 | 1920 | 1800 | 1300 | 115 | 4960×3640 | 25 | 1750×900×700 | 1000 |

| NC300F | 6250 | 4650 | 3360 | 2290 | 3350 | 950 | 2040 | 2000 | 1500 | 130 | 6000×4800 | 35 | 1750×900×700 | 1000 |

| NC300 | 7040 | 5140 | 4130 | 2730 | 4200 | 1010 | 2650 | 2500 | 1800 | 135 | 6660×5200 | 55 | 2300×1000×1000 | 2000 |

| NC400 | 7850 | 6010 | 4890 | 3250 | 4600 | 1150 | 3180 | 3000 | 2000 | 155 | 7480×5950 | 80 | 2300×1000×1000 | 2000 |

| NC500 | 8700 | 7100 | 5400 | 3200 | 5300 | 1400 | 3550 | 3500 | 2500 | 160 | 8100×6300 | 110 | 2300×1000×1000 | 2000 |