Home »Products »Die Spotting Press »Vertical Die Spotting Press (NC Series) » NC70-1007 vertical die spotting press

- Products

- Die Spotting Press

- Vertical Die Spotting Machine

- Horizontal Die Spotting Machine

- Hardware Die Spotting Machine (NCC Series)

- CNC Gun Drilling Machine

- Single Shaft Gun Drilling Machine

- 2-Axis Gun Hole Machine

- 3-Axis Gun Drilling Machine

- 4-Axis Gun Drilling Machine

- Drilling and Milling Compund Machine

- Mold Turnover Machine

- Electric Magnetic Chuck

- Electric Magnetic Chuck for CNC Machine

- Electric Magnetic Chuck for Mobile Phone

- Hydraulic Press Machine

- Horizontal CNC Milling Machine

- CNC Drilling and Milling Machine

- NCB Drawing Press

- Spray and Absorb Drilling Machine

- Rotary Work Bench

- Quick-Die Change System

- Permanent Magner Lifter

NC70-1007 vertical die spotting pressRead More

Description:

NC70-1007 vertical mold spotting machine is mainly applied in repair or verification of plastic die, hardware molding die. The machine has max spotting force 70T, working bench 1000×700mm. The machine is a newly-developed machine on the basis of traditional die spotting press. It adopts electric magnetic chuck, which improves work efficiency and save labor. Besides, it is simple to operate NC70-1007 vertical mold spotting machine with computer control and man/machine interface.

Types:

Application:

The NC70-1007 mold spotting machine is mainly used in repairing and assembling of various plastic mould, or hardware molding die.

Components:

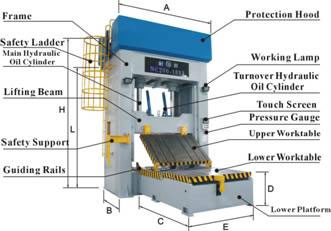

Front view

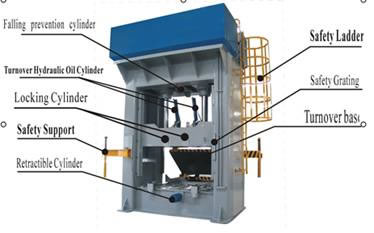

Front view Side view

Side view

Features:

- 1. Large rigidity and small deformation

NC70-1007 mold spotting machine adopts welding type frame structure. Frame and sliding table are processed through tempering treatment, for the advantages of no stress, large rigidity and small formation. - 2. Flatness and high precision

Upper and lower working benches and guide rails of pressure-plate NC70-1007 mold spotting machine are made from nodular cast iron and adopt manual scraping for surface processing, with sound flatness, high precision and small deformation. - 3. Safe and energy-saving

NC70-1007 mold spotting machine supports electric control permanent magnet. It can ensure continuous magnet supply, which is safe and energy-saving. - 4. Perfect safety facilities

There are complete safety facilities to ensure safety, like safety grating, anti-falling oil cylinder, locking cylinder and safety supporting frame and other prevention facilities. - 5. High precision

NC70-1007 mold spotting machine has high precision because hydraulic system adopts vibration-absorption facilities which will reduce hydraulic impact. - 6. Hydraulic system is equipped with low-pressure protection facilities, to prevent damages caused by collision and insertion.

- 7. Good red lead can be achieved because of high speed.

Parameter:

| Model | NC70 vertical mold spotting machine |

| Max spotting force(T) | 70 |

| Max lifting force(T) | 20 |

| Die opening space(mm) | 1100 |

| Size of working bench(mm) | 1000×700 |

| Bearing capacity of upper working bench(T) | 1 |

| Bearing capacity of lower working bench(T) | 3 |

| Suction force of upper magnetic disk(T) | 25 |

| Suction force of lower magnetic disk(T) | 20 |

| Fast up/down speed(mm/s) | 70/70 |

| Slow up/down speed(mm/s) | <25 |

| Eject capacity(T) | 3 |

| Eject stroke(mm) | 100 |

| Out stroke of lower working bench(mm) | 1600 |

| Motor power(KW) | 5.5 |

| Total height of machine(H)(mm) | 4160 |

| Land area of machine(mm) | 3400×3100 |

| Weight of machine(T) | 6.5 |

If you need more information about vertical die spotting machine, please click Quick links:

Inspection Method of Die Spotting Machine | Work Flow of Die spotting press

Related Products:

NC30-0806 vertical die spotting press

NC30-0806 vertical die spotting press

NC50-1007 Vertical Die Spotting Press

NC50-1007 Vertical Die Spotting Press

NC70-1007 Vertical Die Spotting Press

NC70-1007 Vertical Die Spotting Press

NC100-1310 Vertical Die Spotting Press

NC100-1310 Vertical Die Spotting Press

NC120-1310 Hydraulic die spotting press

NC120-1310 Hydraulic die spotting press

NC150-1511 Magneto electric Die Spotting Press

NC150-1511 Magneto electric Die Spotting Press

NC200-1813 Vertical Die Spotting Press

NC200-1813 Vertical Die Spotting Press

NC300F-2015 Vertical Die Spotting Press

NC300F-2015 Vertical Die Spotting Press

NC300-2518 Vertical Die Spotting Press

NC300-2518 Vertical Die Spotting Press

NC400-3020 Vertical Die Spotting Press

NC400-3020 Vertical Die Spotting Press

NC500-3525 Vertical Die Spotting Press

NC500-3525 Vertical Die Spotting Press

NC30-0806 vertical die spotting press

NC30-0806 vertical die spotting press

NC50-1007 Vertical Die Spotting Press

NC50-1007 Vertical Die Spotting Press

NC70-1007 Vertical Die Spotting Press

NC70-1007 Vertical Die Spotting Press

NC100-1310 Vertical Die Spotting Press

NC100-1310 Vertical Die Spotting Press

NC120-1310 Hydraulic die spotting press

NC120-1310 Hydraulic die spotting press

NC150-1511 Magneto electric Die Spotting Press

NC150-1511 Magneto electric Die Spotting Press

NC200-1813 Vertical Die Spotting Press

NC200-1813 Vertical Die Spotting Press

NC300F-2015 Vertical Die Spotting Press

NC300F-2015 Vertical Die Spotting Press

NC300-2518 Vertical Die Spotting Press

NC300-2518 Vertical Die Spotting Press

NC400-3020 Vertical Die Spotting Press

NC400-3020 Vertical Die Spotting Press

NC500-3525 Vertical Die Spotting Press

NC500-3525 Vertical Die Spotting Press