- Products

- Die Spotting Press

- Vertical Die Spotting Machine

- Horizontal Die Spotting Machine

- Hardware Die Spotting Machine (NCC Series)

- CNC Gun Drilling Machine

- Single Shaft Gun Drilling Machine

- 2-Axis Gun Hole Machine

- 3-Axis Gun Drilling Machine

- 4-Axis Gun Drilling Machine

- Drilling and Milling Compund Machine

- Mold Turnover Machine

- Electric Magnetic Chuck

- Electric Magnetic Chuck for CNC Machine

- Electric Magnetic Chuck for Mobile Phone

- Hydraulic Press Machine

- Horizontal CNC Milling Machine

- CNC Drilling and Milling Machine

- NCB Drawing Press

- Spray and Absorb Drilling Machine

- Rotary Work Bench

- Quick-Die Change System

- Permanent Magner Lifter

NC30-0806 vertical die spotting pressRead More

Description:

NC30-0806 vertical die spotting press is mainly applied in repair or verification of plastic die, hardware casting die. With. max spotting force 30T, workbench 800×600mm. NC30-0806 die spotting press is fit for medium and large mold. On the basis of traditional vertical die spotting, NC30-0806 die spotting press adopts electric magnetic chuck, thus it is unnecessary to fix screws. Thus, it can greatly improve work efficiency and save labor. Besides, the mould can be turned from 0-180. It is easy to operate NC30-0806 vertical die spotting press with computer control and man/machine interface.

Model:

Application:

NC30-0806 vertical die spotting press is mainly applied in repair or verification of plastic die, hardware casting die,is the main product of our company which takes a great effort and time of our technician to develop. It absorbs the essence of products at home and abroad. NC30-0806 vertical die spotting press replaces the traditional simple fitting of knocking by copper bar because of its fast and automation operation, which greatly improves efficiency and precision of die spotting press.

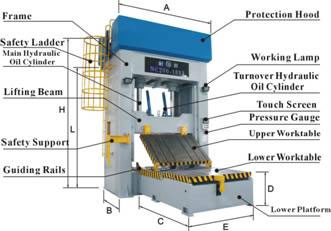

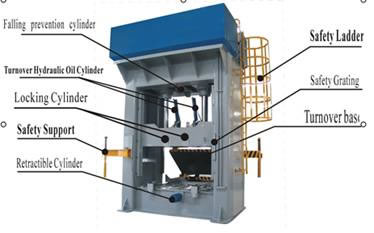

Components:

Front view

Front view Side view

Side view

Features:

- 1. Perfect safety facilities

There are complete safety facilities to ensure reliability and safety, like safety grating, anti-falling oil cylinder, locking cylinder and safety supporting frame and other prevention facilities. - 2. High precision

NC30-0806 vertical die spotting press has high precision because hydraulic system adopts vibration-absorption facilities which will reduce hydraulic impact. - 3. No damage

Hydraulic system is equipped with low-pressure protection facilities, to prevent damages caused by collision and insertion. - 4. Good red lead can be achieved because of high speed.

Parameter:

| Model | NC30 vertical die spotting press |

| Max spotting force(T) | 30 |

| Max lifting force(T) | 12 |

| Die opening space(mm) | 1000 |

| Size of work bench(mm) | 800×600 |

| Bearing capacity of upper working bench(T) | 0.5 |

| Bearing capacity of lower working bench(T) | 2 |

| Suction force of upper magnetic disk(T) | 20 |

| Suction force of lower magnetic disk(T) | 15 |

| Fast up/down speed(mm/s) | 70/70 |

| Slow up/down speed(mm/s) | <25 |

| Eject capacity(T) | 3 |

| Eject stroke(mm) | 100 |

| Out stroke of lower working bench(mm) | 1400 |

| Motor power(KW) | 4.0 |

| Total height of machine(H)(mm) | 3300 |

| Land area of machine(mm) | 3200×2900 |

| Weight of machine(T) | 4.8 |

If you need more information about die spotting machine, please click Quick links:

Inspection Method of Die Spotting Machine | Work Flow of Die spotting press NC30-0806 vertical die spotting press

NC30-0806 vertical die spotting press

NC50-1007 Vertical Die Spotting Press

NC50-1007 Vertical Die Spotting Press

NC70-1007 Vertical Die Spotting Press

NC70-1007 Vertical Die Spotting Press

NC100-1310 Vertical Die Spotting Press

NC100-1310 Vertical Die Spotting Press

NC120-1310 Hydraulic die spotting press

NC120-1310 Hydraulic die spotting press

NC150-1511 Magneto electric Die Spotting Press

NC150-1511 Magneto electric Die Spotting Press

NC200-1813 Vertical Die Spotting Press

NC200-1813 Vertical Die Spotting Press

NC300F-2015 Vertical Die Spotting Press

NC300F-2015 Vertical Die Spotting Press

NC300-2518 Vertical Die Spotting Press

NC300-2518 Vertical Die Spotting Press

NC400-3020 Vertical Die Spotting Press

NC400-3020 Vertical Die Spotting Press

NC500-3525 Vertical Die Spotting Press

NC500-3525 Vertical Die Spotting Press